High-frequency welding of PU/PVC on fabric screens (200–5000 µm mesh): seamless, food/pharma grade, flat, burr-free & TÜV-verified by Fraunhofer. Made in Germany.

HF Welding

Processes

On our HF equipment we can create seams, which are significantly stronger than sewn designs.

By means of high frequency waves (similar to microwaves) PU or PVC weld-on tapes are softened and pressed on the fabric. The molten material completely encloses the fibers of the screening fabric and a homogenous, extremely stable seam is created.

Applications

Due to its smooth surface the HF seam is particularly recommended for screens for the food and pharmaceutical industries.

There are no depressions, in which the product could deposit. Furthermore, the seam is only insignificantly thicker than the fabric itself.

Currently we manufacture screens with HF seam from 200 µm to 5.000 µm mesh size.

Seam width according to fabric mesh size.

Carbon or metal fabric cannot be welded for process technology reasons.

Good Vibrations - Perfect connection with HF seam

Quality

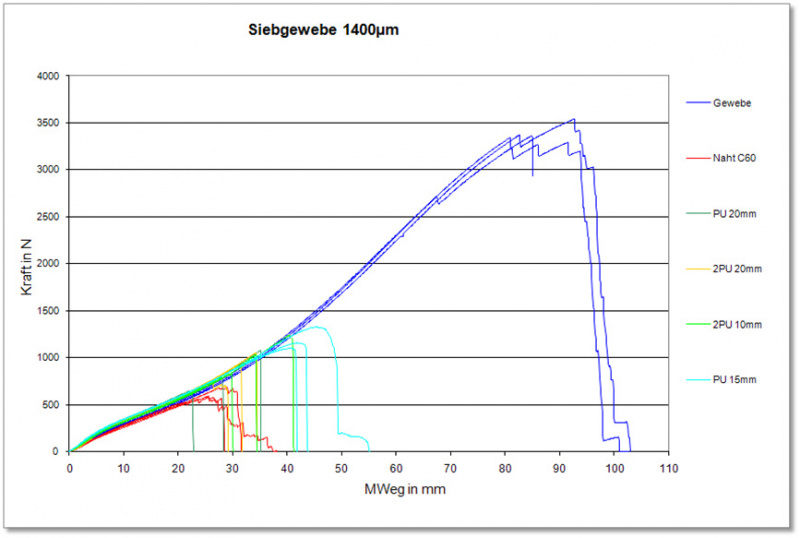

The stability of the seams was proven in cooperation with the Fraunhofer Institute Freiburg in the framework of a subsidy program for innovative projects in Baden-Württemberg .

Tensile tests were performed on reinforcement strips made of mesh with different mesh widths (600 µm, 1,400 µm, 5,000 µm). They were in each case compared with matching weld/ welded reinforcement strips.

The result showed: ...that HF-welding produced a good “adhesive connection” that can withstand higher loads than welded mesh connections of the same mesh width...

(from IWM-Bericht 528/2010 Fraunhofer IWM)